Cyclohexanone is an important chemical raw material, which is the main intermediate in the manufacture of nylon, caprolactam and adipic acid. It is also an important industrial solvent.

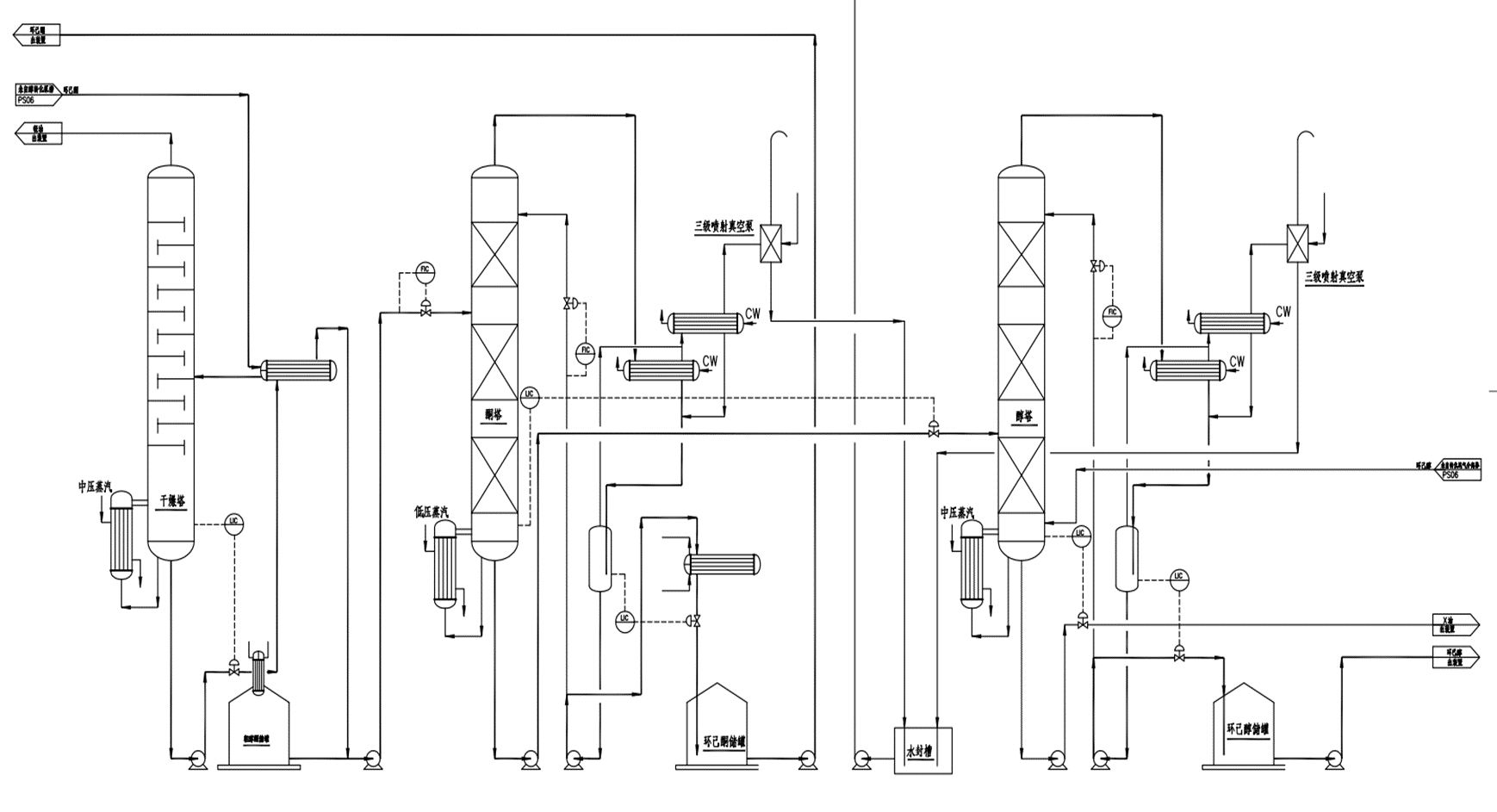

In the traditional cyclohexanone production process, steam ejector is generally used as the vacuum source of the system. The disadvantages of this equipment include high energy consumption, large amount of waste water, complex waste water treatment system, unable to recycle the alcohol ketone in the gas, and high cost of tail gas treatment. Original steam ejector (as shown below).

In order to solve this series of shortcomings and problems, the equipment is more suitable for the process of cyclohexanone. The APUMP process design team, after accurate process calculation, technically modified the dry vacuum system for this process.

The innovative dry vacuum system is used to replace the original steam ejector vacuum system, which has high operating efficiency.Low energy consumption in operation; Zero discharge of sewage; Low exhaust treatment cost; Alcohol ketone recovery clean; Increased economic and environmental benefits; The vacuum degree of the system is constant without fluctuation; Low input of waste water treatment equipment; Zero increase in operating costs; Small footprint and other advantages.

The dry vacuum system also has the following features:

a. High security: reliable equipment, low failure rate, to ensure the safety and stability of the system operation;

b. Quality assurance: Overcome high melting point components, stable tower pressure, to ensure product quality;

c. One-key start-stop: convenient operation, unattended, remote monitoring;

d. Energy saving: no steam consumption, low power consumption;

e. Clean recovery: clean recovery of cyclohexanone, cyclohexanol and other components.

Are you looking for reliable vacuum system solution?

Company address: No. 67, Feiying Road, Binjiang Development Zone, Jiangning District, Nanjing

Tel: 025-86211588

Enterprise Email: apump@apump.com.cn

400-888-6662

©2021 Nanjing Vacuum Pump Factory Co., Ltd. Recordation number: Su ICP No. 2022028646-1